If you are a shop owner/manager or an operator who want to confront the issues of tool deterioration, chip formation and evacuation, and improve their turning results. Then this is for you!

Tool life, workpiece quality and workflow productivity all add up to drive or impede your shop's profitability as well as your customer relationships.

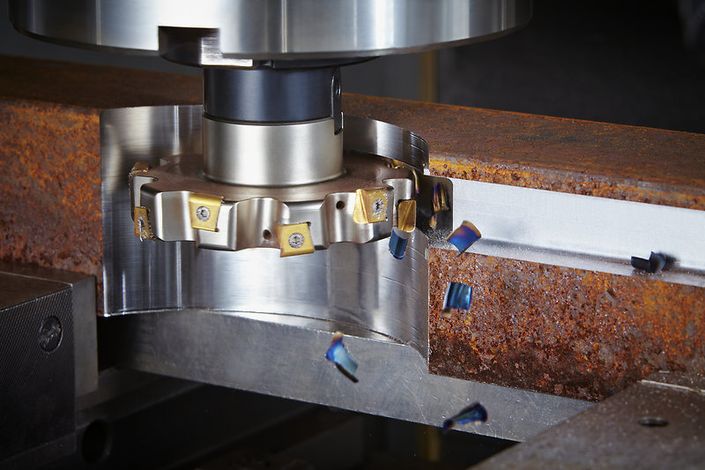

This course helps you implement practical approaches to the challenges of turning many types of jobs and materials. It covers productive approaches to chip formation and evacuation; minimization of tool breakage, deterioration and unduly short tool life; and achieving productivity in a diverse range of reliable, cost-effective, sustainable turning applications.

You will learn how to make correct tool selections, set up machines properly for a productive cut and avoid both work in progress and unnecessarily large tool acquisitions. Gain practical insights into ways to optimize chip formation, tool wear, and your selection of chipbreaker geometry and carbide grades.